Hello everyone!

Since TLG released 76023, I had been waiting for affordable Technic set

which includes so-called Tumbler Tires. So I jumped at 42050 Drag Racer.

I also bought some extra tires separately, then revived old project

which had failed three years ago.

Avtoros Shaman 8x8

Weight: 2550g

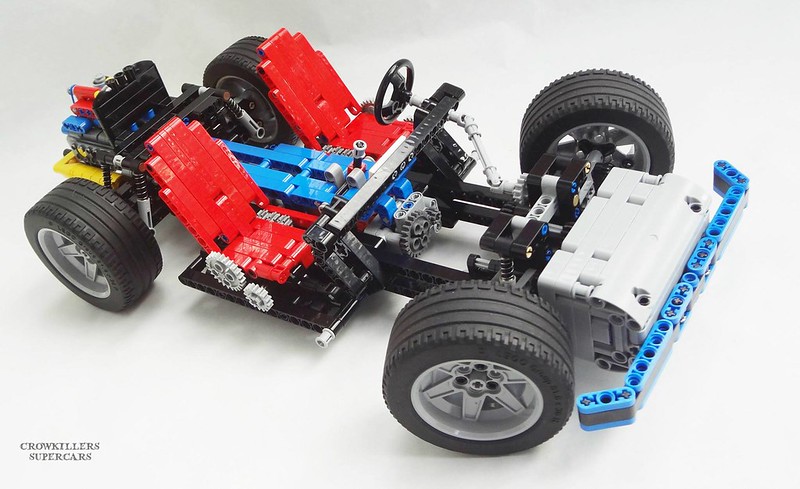

- 4x L motor for 8 wheel drive

- 2x Servo motor for 8 wheel steering

- M motor for switching steering mode (AWS and crab)

- M motor for winch

- 3x LED for front and rear lights

- 2x SBrick powered by 2x 8878 rechargeable battery box

- Independent suspension for all wheels

- Working steering wheel

- Openable hood, doors and roof hatch

Back in 2013

As you may know, real Shaman is

Massive Russian ATV which can go through almost any kind of terrain.

It has three steering modes and can scale 45-degree incline. On top of

that it is amphibious. Seeing pictures and videos, I instantly fell in

love with it.

When I started the project, I was too ambitious to realize all features

above. Sadly I could not build even steering mechanism while keeping all

wheel drive and independent suspension. So I changed the project to

building another 8x8 vehicle. It ended up as my Tatra 813 Trial Truck,

but that is another story.

Focus on characteristic features

Focus on characteristic features

Two months ago, I suddenly came up with an idea that enables both normal

AWS and crab steering. In the case of four-wheeler, you can do it by

switching rotation of second Servo motor for rear axle. But in

eight-wheeler like Shaman, you should change turning radius of second

and third axle.

In normal mode, the steering angle of inner two axles is smaller than outer axles.

But in crab mode, all axles should be steered at the same angle.

This is the basis of steering idea. I used the way of fixing/moving pivot of steering linkage.

A:

A: There are two 7L steering racks

connected to 7L beams. Front rack is connected in the middle of beam,

rear is one stud backwards. Both ends of beams are connected to steering

arms of each axle.

B: In normal mode, rear rack is fixed by

12T bevel gear. So the fixed pivot of 7L beam is its 5th pin hole. Which

makes front end of beam moves twice as rear end does. That means the

steering angle of 1st axle is twice as 2nd axle.

C: In switching crab mode, 12T bevel gear

moves one stud forward and fix front rack. Fixed pivot is 4th pin hole

of beam. Which makes both ends of beams move equally. That means the

steering angle of 1st axle is the same as 2nd axle.

And there is one more twist.

D: I put main steering rack (moved by

pinion gear) on one stud forward of 7L beam's front-end (which means 9L

beam’s front-end). Seeing from the pivot point, this rack is connected

to farther than the point of front steering arms connected. So front

steering arms always move slightly shorter than main rack does. When

Servo fully turns 90 degrees, pinion gear moves the rack in one stud

sideways. Steering arms move less than one stud. This was necessary for

keeping CV joint (connected to steering hub) rotate smoothly even when

fully steered.

Challenge and compromise

Challenge and compromiseFirst of all, this MOC is NOT amphibious. It is too heavy to float. And

because of driving motors of low position, chassis is not waterproof at

all. So it is not recommended driving it through even shallow water

pool.

My aim was to achieve decent crawling capability. But I had to lower the

bar because there was no room left for portal/planetary hub reduction.

Without them, heavy load from 81mm tires directly goes to 12T half bevel

gears.

First attempt was using two XL motors geared 25:9. I put each motor for

left/right side of axle. The result was unsatisfied. Even when climbing

over small obstacles, bevel gears often slipped and got damaged.

So I replaced them with four L motors geared 3:1. Each one drives a pair

of half axles. Thanks to their good speed and smaller torque, new

drivetrain proved to be more reliable. Although bevel gears were still slipping a bit, I accepted overall performance.

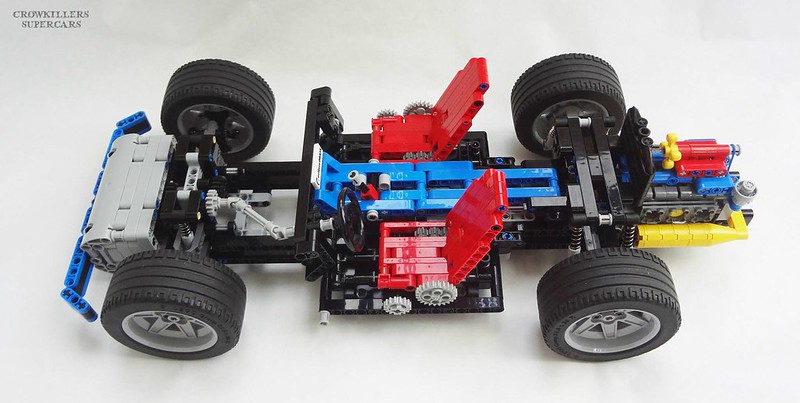

The picture above shows two L motors for driving right side of axles.

The power functions switch for changing rotation of rear Servo motor is

synchronized with moving steering pivot mechanism. In crab mode, rear 4

wheels steer

opposite the same direction as front wheels.

As always I used few of non-Technic parts. Big roof tile was used for

saving weight, curve slope parts were better choice for filling the gap.

LBG axles sticking out the roof are visible indicator for steering

mode. They are mechanically connected to switching mechanism. In the

video you can see how they work.

Instructions of white version will be available. (Building it in red is

possible by using red parts instead of white.) It will take more than

weeks because building process was complicated. So please wait.

Original Topic: http://www.eurobricks.com/forum/index.php?showtopic=137034

Original Topic: http://www.eurobricks.com/forum/index.php?showtopic=137034